How to build a deterministic industrial Ethernet system

Enhanced network connectivity mechanisms, developed through the cooperation of related standards groups, have given Ethernet (802.3) the robust qualities required to operate effectively in operational and safety-critical environments.

As a result, manufacturing environments and building automation systems are rapidly adopting Ethernet in compliment with, or as a replacement for, the various fieldbus technologies traditionally used in these environments.

In a typical building or factory network, there may be a number of network domains, each with varying degrees of timing and safety constraints. These may range from the management and operation environments, where standard IT equipment is utilized over Ethernet, to industrial Ethernet-based and fieldbus networks operating in manufacturing or safety critical environments.

More recently, enhanced mechanisms developed by industry standards groups, such as IEEE 1588, have given Ethernet the deterministic qualities needed to function in operational and safety critical environments.

As a result, factory networks and building automation systems are adopting Ethernet to compliment, and in some cases to replace, various fieldbus technologies currently in use.

To support such a diverse protocol domain, where both fieldbus and Ethernet co-exist, requires a versatile, cost-effective communication processor capable of supporting a diverse range of interconnects and low-level protocol processing.

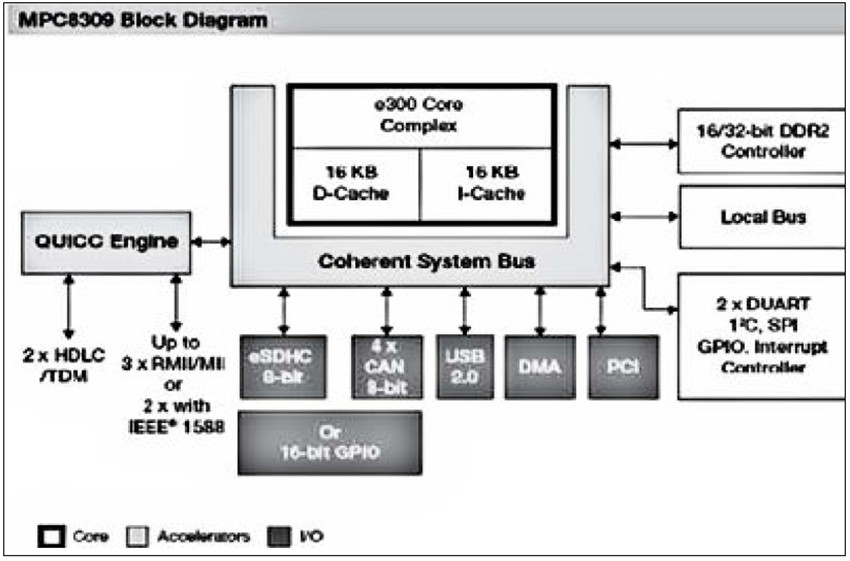

To address the need for enhanced connectivity between the diverse network domains in the modern industrial market, Freescale Semiconductor has launched the MPC8309 (figure 1) and MPC8306/S embedded processors.

The new processors extend the MPC830x PowerQUICC II Pro processor portfolio into the entrylevel industrial and networking applications, with DDR2, 10/100 Ethernet and IEEE 1588 support, PCI 2.3 (available on MPC8309 only), USB2.0, CAN and enhanced interfaces to support both legacy and emerging protocols used in the industrial networking market.

Factory network

A typical factory network may consist of a number of domains, each with varying degrees of timing or safety constraints.

These range from management systems, where standard IT equipment is used over traditional Ethernet, to industrial Ethernetbased networks being deployed in plant or manufacturing environments, as well as serial-based fieldbus networks.

In the control and field domains, there are a range of nodes and network connectivity options deployed to provide safety, supervisory, process and logic control over the field equipment. In order to connect standard Ethernet-based management systems to the production floor, where networked controllers are typically communicating with one another using industrial protocols such as PROFIBUS, CANopen or DeviceNET, some type of bridging solution is required. This diverse protocol domain, where both fieldbus and Ethernet co-exist, is a prime opportunity for the application of an SoC design.

The integration of a highperformance, power-efficient processor core, together with an optimized blend of interconnect and low-level protocol processing capabilities, can deliver the platform flexibility needed to support the broad spectrum of Industrial processing nodes used today in factory automation applications, including programmable logic controllers, process automation controllers, intelligent I/O, operator interface terminals, drives and bar-code & ID systems.

Industrial interconnect

SoC platforms, which include a processor core together with a combination of peripheral interfaces on a single integrated chip, have become widely popular in the standard IT market due to their design efficiency and cost effectiveness.

For an SoC to effectively address the bridging requirements between the disparate network domains of modern industrial or factory automation environments, the integration of several inter- faces used to support fieldbus, as well as Ethernet, is required.

An optimal mix would include SPI, I2C, CAN, RS485, TDM, PCI, and Ethernet. In addition to these, the following interfaces and protocols are also recommended to support modern memory and associated peripheral devices: UART (supporting PC16450 and PC16550 programming models), DDR2 SDRAM (with ECC support), USB 2.0, IEEE 1588 for clock synchronization of networked nodes, and a suitable number of GPIOs – with all pins supporting interrupt capability.

Serial-based fieldbus protocols in use today include PROFIBUS, CAN and DeviceNET. The CAN module utilized in a SoC design should support the version 2.0 specification and be backwards compatible with the previous 1.0 module version.

Industrial Ethernet-based protocols in use include PROFINET, EtherCAT and CANopen. Implementation of IEEE 1588 support for Ethernet should support the version 2.0 specification. The IEEE 1588 protocol enables heterogeneous systems that may include clocks of various inherent precision, resolution and stability to all be synchronized across the network.

A hardware-assisted implementation of IEEE 1588 would support system-wide synchronization accuracy in the sub-microsecond range with minimal network and local clock computing resources. RF connectivity solutions, such as 802.15.4 or ZigBee technology, should be provided by the PCI controller supporting version 2.3.

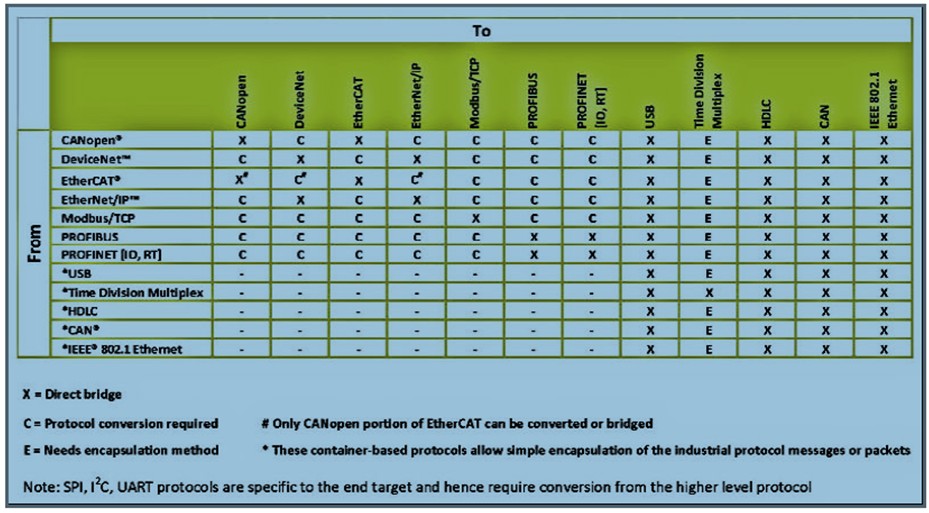

Industrial Ethernet/Fieldbus Bridging. A SoC designed with the aforementioned interfaces and features would be able to implement multiple protocols and should support both Master and Slave functionally for each.

Such an SoC could also provide a bridging function between similar or dissimilar protocols. For example, a similar protocol bridging would be from PROFIBUS to PROFINET where only the physical connectivity is changing. A dissimilar protocol bridging example would be where CAN was converted into a PROFINET.

In this case, the conversion would require the complete termination of each protocol to the point where a common mapping of function/telemetry can be achieved. A matrix of possible bridging combinations is shown in the table.

MPC8309, MPC8306/S

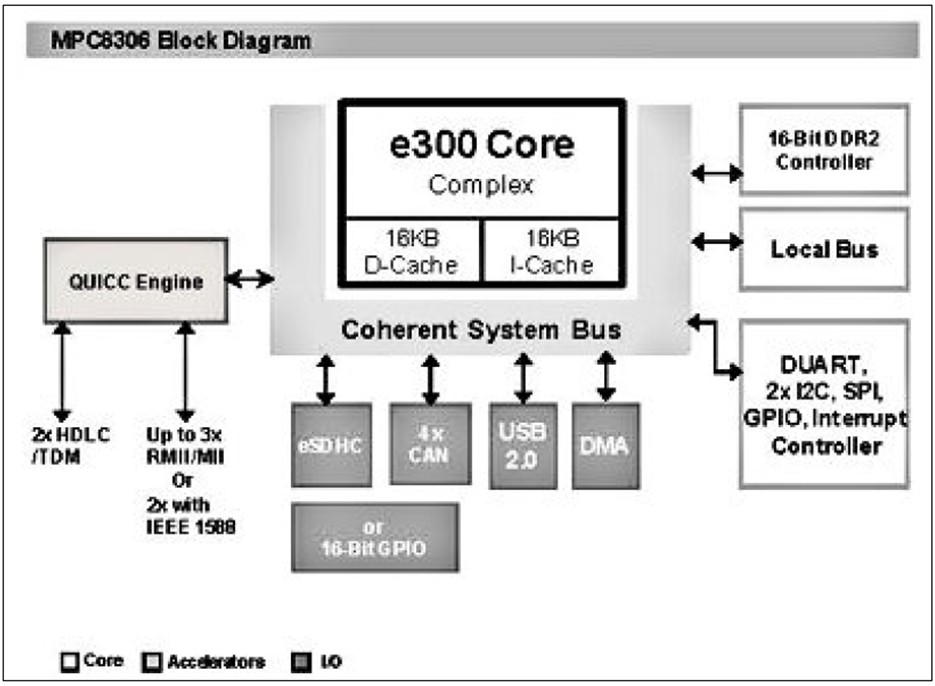

Both the MPC8309 and MPC8306/S processors (figure 2) incorporate the e300c3 processor core, built on Power Architecture technology, that yields 1.99 DMIPS/MHz, and is available in frequencies from 266 MHz up to 400 MHz. Both processor cores include 16 KB of L1 instruction and data caches, dual integer and on-chip memory management units (MMUs). Both processors also feature an on-chip DDR2 memory controller with error correction (ECC) support for improved performance and cost effectiveness

The MPC8309 and MPC8306/S processors both feature Freescale’s QUICC Engine offload technology, designed to support a range of industrial protocols without having to utilize core processor resources.

Industrial Ethernet and fieldbus support have been added, as well as support for IEEE 1588 timing synchronization. Industrial interface ports featured on both the MPC8309 and MPC8306 include 4x CAN, 4x UARTS, SPI and SDIO.

In addition to industrial applications, the MPC8309 processor is also suited for networking applications including I/O cards for low-end base stations, low-end Ethernet switches and modems.

For those customers using PowerQUICC I or PowerQUICC II products, the MPC8309 and MPC8306/S provide a migration path by offering industrial interfaces while maintaining code compatibility with these legacy processors.

The MPC8306 is a CPU that offer 530 DMIPs. The MPC8309 adds 32-bit PCI 2.3 support, as well as 32/16-bit DDR2 memory bus and up to 800 DMIPs with less than 1.5W typical.

The MPC8309 processor is packaged in a 19 mm x19 mm 489-pin MAPBGA with a tight pitch at 0.8mm that enables a compact, low-layer board and smaller overall footprint. Low power dissipation eliminates the need for external heat dissipation techniques and allows fan-less designs. The integration of serial interfaces reduces board size and a 16/32-bit DDR2 memory controller enables memory designs.